Tape cores and label cores are cylindrical structures around which adhesive tapes and labels, respectively, are wound for storage and dispensing. While tape cores hold adhesive tapes, such as packing tapes used for sealing boxes, label cores serve as the foundation for label rolls, including barcode labels, product information labels, and promotional stickers. Read More…

Valk Industries provides engineering and manufacturing services for cardboard tubes as well as custom thermoformed items like clamshells, blister packs, trays and filler material.

Western Container partners with the world`s top spiral tube equipment designers & paperboard manufacturers, to bring our customers the very best paper tubing and precision cores.

Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical. CMT has been meeting custom size and design requirements for its customers since 1902.

Here at Paper Tubes and Sales we are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams are available to assist you with determining the best paper tube for your application.

Marshall Paper Tube Company designs and manufactures custom labeled cans, tubes, and mailings. We can create amazing custom designs in full color for your product or brand. We also provide specialty items like coin collection banks and fundraising cans. All of our products are made in the United States of America and out of 100% recycled paperboard in an effort to stay “green.”

More Tape Cores and Label Cores Manufacturers

Benefits of Custom Tape and Label Cores

Brand Identity:

Custom tape cores and label cores provide a unique branding opportunity. Businesses can print their logos, slogans, and other brand elements directly onto these cores, ensuring their presence is visible throughout the packaging process.

Professionalism:

Branded tape cores and label cores convey a sense of professionalism and attention to detail. When customers receive packages with branded tapes and labels, they perceive the brand as reliable and quality-oriented.

Aesthetics:

Customization allows businesses to align the design of tape cores and label cores with their overall packaging aesthetics. This creates a cohesive and visually appealing unboxing experience, leaving a lasting impression on customers.

Ease of Identification:

Custom label cores with clear and consistent information help warehouse staff quickly identify the right labels for various products, reducing errors and increasing operational efficiency.

Market Differentiation:

In a saturated market, businesses need to stand out. Unique tape cores and label cores can set a brand apart from competitors and leave an impression on customers, potentially leading to repeat business and word-of-mouth referrals.

Types of Materials for Custom Tape and Label Cores

Cardboard:

Cardboard cores are a popular choice for both tape and label cores due to their affordability and versatility. They are lightweight and can be easily customized with printing. However, they might not be the best option for applications where moisture or extreme conditions are a concern.

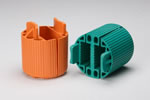

Plastic:

Plastic cores, often made from materials like polypropylene, offer greater durability and resistance to moisture and chemicals. They are suitable for tapes and labels used in outdoor environments or industries that require more robust protection.

Metal:

Metal cores, such as aluminum, provide the highest level of durability and strength. These are commonly used for heavy-duty applications, industrial settings, and situations where the cores need to withstand significant weight and stress.

Print Design for Custom Tape and Label Cores

Digital Printing:

Digital printing offers flexibility and allows for intricate designs and vibrant colors. It is suitable for smaller quantities and offers a cost-effective solution for businesses with diverse branding requirements.

Offset Printing:

Offset printing provides high-quality, consistent results for larger quantities. It offers precise color matching and can accommodate a wide range of designs. This method is ideal for businesses looking for a polished and professional appearance.

Screen Printing:

Screen printing is a versatile method suitable for both simple and complex designs. It can provide vibrant colors and a tactile finish. While it may be more labor-intensive for smaller quantities, it can be cost-effective for larger production runs.

Sustainable Custom Tape and Label Cores

Recyclable Materials:

Opt for materials that are easily recyclable. Cardboard cores are more environmentally friendly compared to plastic or metal cores. Additionally, consider using materials that have recycled content to further minimize the ecological footprint.

Biodegradability:

If suitable for your application, explore options for biodegradable or compostable materials. These choices align with eco-conscious trends and demonstrate a commitment to environmental responsibility.

Considerations for Custom Tape and Label Cores

Budget:

Customization can lead to higher production costs compared to generic cores. Businesses should weigh the benefits against the increased expenses to ensure a positive return on investment.

Volume:

The volume of tapes and labels used influences the feasibility of customization. Higher quantities may lead to reduced per-unit costs.

Supplier Collaboration:

Partnering with a reliable supplier capable of producing high-quality customized cores is crucial. A trustworthy supplier will ensure consistency, accuracy, and timely delivery.

How to Find a Custom Tape Core or Label Core Manufacturer

When purchasing tape cores and label cores from a tape core and label core manufacturer, compare at least 4 or 5 manufacturers using our list of tape core and label core manufacturers. Each tape core and label core manufacturer has a business profile page which highlights their areas of experience and capabilities, and has a contact form to directly communicate with the manufacturer for more information or request a quote. Review each tape core and label core business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple tape core and label core businesses with the same quote.

Choosing the right custom tape core or label core manufacturer involves several important factors to consider. Here are some steps to guide you through the selection process:

Quality and Materials:

Research manufacturers that specialize in producing high-quality cores. Look for manufacturers that use durable materials, like sturdy cardboard or plastic, which can withstand the weight and tension of the tape or labels wound around them.

Customization Options:

Ensure the manufacturer can create cores tailored to your specific requirements. This includes considering the core's diameter, length, thickness, and any special features or coatings you might need.

Experience and Reputation:

Choose a manufacturer with a proven track record in producing cores for the tape and label industry. Read reviews, testimonials, and case studies to gauge their reputation and level of expertise.

Technological Capabilities:

A manufacturer that invests in advanced manufacturing technology is more likely to produce consistent and high-quality cores. Advanced equipment can also allow for customization and precision.

Production Capacity:

Consider the manufacturer's production capacity. Can they handle your order volume within your desired timeline? It's important to choose a manufacturer that can meet your needs, whether you require a small batch or a large production run.

Customization Flexibility:

Some manufacturers might have minimum order quantities or limited customization options. Make sure the manufacturer can accommodate your specific customization needs and align with your production plans.

Sampling and Prototyping:

Request samples or prototypes before placing a larger order. This allows you to assess the quality, dimensions, and any additional features of the cores to ensure they meet your requirements.

Cost Considerations:

While cost is a factor, prioritize quality and performance over choosing the cheapest option. The cores' durability can impact your end product's performance, so it's worth investing in well-made cores.

Communication and Support:

Good communication and responsive customer support are essential. A manufacturer that collaborates effectively and addresses your concerns promptly can streamline the production process.

Environmental Responsibility:

Consider manufacturers that prioritize sustainable practices. Using eco-friendly materials and recycling options can align with your company's values and contribute to a greener supply chain.

Location and Shipping:

The manufacturer's location can impact shipping costs and delivery times. If you're looking for a quick turnaround, working with a manufacturer located closer to your business might be beneficial.

Legal and Contractual Considerations:

Ensure you understand the terms of the manufacturer's contract, including payment terms, lead times, quality guarantees, and any warranties provided.

References and Recommendations:

Seek recommendations from industry peers or associates who have experience with tape core or label core manufacturers. Their insights can provide valuable guidance.

Remember that finding the right manufacturer might take some time, but thorough research and careful consideration of these factors will help you make an informed decision that aligns with your business's needs and goals. As the packaging landscape continues to evolve, embracing customization can be a strategic move that sets a business apart and leaves a lasting impression.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services